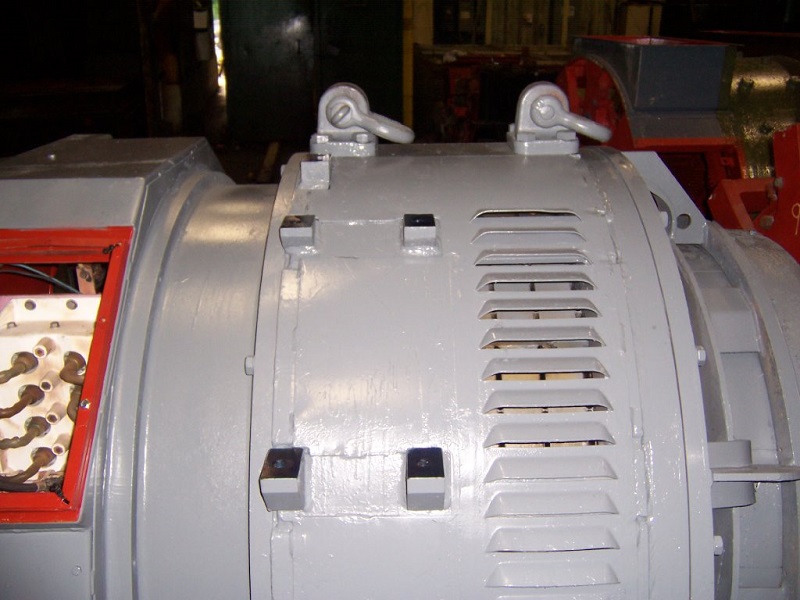

AR-10 Generator

All J&L Generators undergo the same vigarous rebuild process.

DISASSEMBLE , STEAM CLEAN.AND BAKE DRY ARM., ROTOR, AND STATOR ASSEMBLY.

ELECTRICAL TESTS:

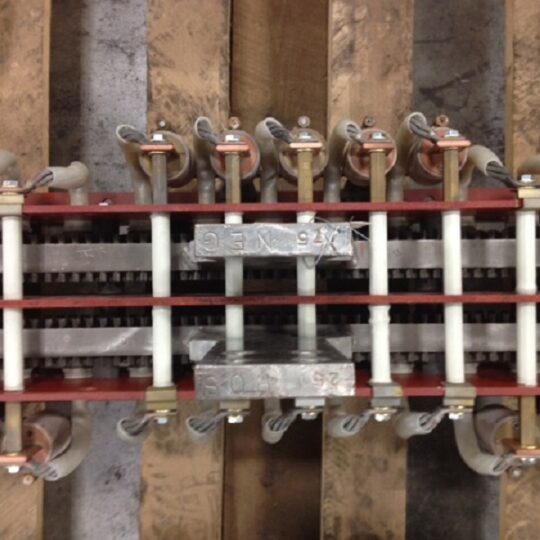

a. MEGOHM TEST ARM. AND STATOR COILS, COLLECTOR RING ASSEMBLY

b. DC HI-POT. TEST ARM., STATOR, & ROTOR COILS

c. BAR TO BAR TEST ARMATURE COMMUTATOR

d. COLD RESISTANCE TEST ON THE COMPANION ALTERNATOR COILS

CHECK ALL MACHINE FITS FOR PROPER WEAR TOLERENCE:

a. INSPECT ALL BOLT HOLE THREAD CONDITIONS

b. INSPECT GENERATOR MOUNTING SURFACES

c. INSPECT COUPLING DISC, BOLTS AND NUTS FOR DEFECTS

d. CHECK ARMATURE BEARING HOUSING FIT

e. INSPECT WEAR ON ALL BEARING SLINGERS, & SPACERS

f. INSPECT WEAR IN ALL BRUSH HOLDER BRUSH BOXES

g. TEST BRUSH HOLDER SPRING TENSION

h. INSPECT SHAFT EXTENSION FOR WEAR OR DEFECTS

i. MEASURE COMMUTATOR DIAMETER FOR WEAR TOLERENCE

j. INSPECT CABLE LEADS, AND TERMINAL CONDITIONS

k. INSPECT COM. BARS AND COM. DIAMETER

L. TURN, MILL, AND UNDERCUT COMMUTATOR. POLISH COLLECTOR RINGS

EPOXY VARNISH DIP ARMATURE, STATOR, COMPANION ROTOR, COMPANION STATOR, AND BAKE TO CURE.

DYNAMICALLY BALANCE ARMATURE.

APPLY A NEW ARMATURE BEARING.

RECONDITION BRUSH HOLDERS (GLASS BEAD & CLEARCOAT EXTERIOR).

SHRINK SLEEVE CABLE LEADS AS NECESSARY

RE-ASSEMBLE STATOR, ARMATURE, COMPANION ROTOR & STATOR, AND INSTALL RECONDITIONED BRUSH HOLDERS.

INSTALL NEW CARBON BRUSHES,

PAINT EXTERIOR GRAY ENAMEL.

PLASTIC WRAP FOR MOISTURE CONTROL.

PREPARE FOR LOADING.